SBF

For Booster Hose

- Super Booster (SB) aluminum construction reels weigh up to 30% less than standard booster reels.

- Gear-driven crank rewind is standard. Choose chain and sprocket drive powered by electric, hydraulic, or compressed air motor.

- Pinion brake standard.

- Standard inlet: 1" 90° ball bearing swivel joint with 1" female NPT threads.

- Standard outlet: 1" male NST threads (1.375" x 8 threads per inch.)

- Consult factory for other sizes and/or threads.

- Standard inlet, outlet riser, and hub assembly are steel (also available in stainless steel).

- Rollers and roller mounting brackets are accessory items. Specify roller position.

- Standard pressures to 1000 psi (69 bar).

- Standard fluid temperatures from -40° F to +250 °F (-40° C to +121° C).

- Consult factory for reels to operate at other pressures and temperatures.

- CAUTION: When using Niedner|Altra® hose, a special riser and/or larger drum diameter is required.

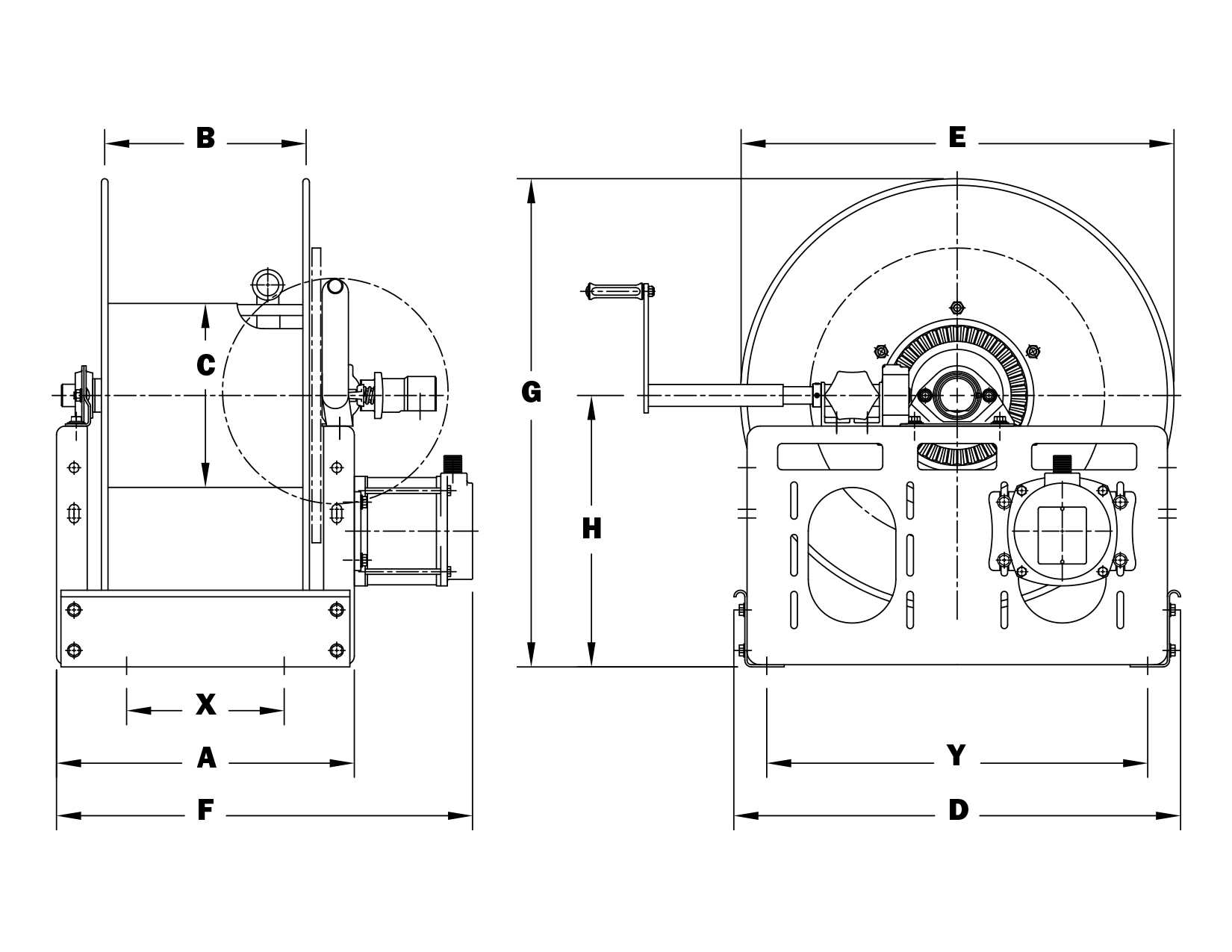

Models shown above represent standard configuration

Left: electric rewind (SBEF), Right: manual rewind (SBF)

Jump to:

Reel Capacity, Dimensions and Details

ISO Parts Drawing

Service Information

Reel Capacity, Dimensions and Details

Reel Capacity:

Show:

Rewind Option:

Show:

Measurements: Standard / Metric

| MODEL | REEL CAPACITY (ft / lbs) | REEL DIMENSIONS (inches) | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Size | Length | Weight | A | B | C | D | E | F | G | H | X | Y | Relative Size | |

| SBF32-19-21-10.5 | 3/4 ID | 175 | 86 | 29.5 | 24 | 10.5 | 20.5 | 21.62 | 34.25 | 21.5 | 12.12 | 21.5 | 16.75 | |

| SBF32-19-21-10.5 | 1 ID | 85 | 86 | 29.5 | 24 | 10.5 | 20.5 | 21.62 | 34.25 | 21.5 | 12.12 | 21.5 | 16.75 | |

| SBF24-23-24-10.5 | 3/4 ID | 150 | 79 | 21 | 15.5 | 10.5 | 20.5 | 23 | 25.75 | 23.5 | 12.12 | 13 | 16.75 | |

| SBF24-23-24-10.5 | 1 ID | 125 | 79 | 21 | 15.5 | 10.5 | 20.5 | 23 | 25.75 | 23.5 | 12.12 | 13 | 16.75 | |

| SBF30-23-24-10.5 | 3/4 ID | 225 | 88 | 27.5 | 22 | 10.5 | 20.5 | 23 | 32.25 | 23.5 | 12.12 | 19.5 | 16.75 | |

| SBF30-23-24-10.5 | 1 ID | 200 | 88 | 27.5 | 22 | 10.5 | 20.5 | 23 | 32.25 | 23.5 | 12.12 | 19.5 | 16.75 | |

| SBF38-23-24-10.5 | 3/4 ID | 300 | 100 | 35 | 29.5 | 10.5 | 20.5 | 23 | 39.75 | 23.5 | 12.12 | 27 | 16.75 | |

| SBF38-23-24-10.5 | 1 ID | 250 | 100 | 35 | 29.5 | 10.5 | 20.5 | 23 | 39.75 | 23.5 | 12.12 | 27 | 16.75 | |

| SBF28-25-26-10.5 | 3/4 ID | 275 | 93 | 25.5 | 20 | 10.5 | 25.5 | 24.75 | 30.25 | 27.88 | 15.5 | 17.5 | 21.75 | |

| SBF28-25-26-10.5 | 1 ID | 175 | 93 | 25.5 | 20 | 10.5 | 25.5 | 24.75 | 30.25 | 27.88 | 15.5 | 17.5 | 21.75 | |

| SBF34-25-26-10.5 | 3/4 ID | 350 | 99 | 31.5 | 26 | 10.5 | 25.5 | 24.75 | 36.25 | 27.88 | 15.5 | 23.5 | 21.75 | |

| SBF34-25-26-10.5 | 1 ID | 250 | 99 | 31.5 | 26 | 10.5 | 25.5 | 24.75 | 36.25 | 27.88 | 15.5 | 23.5 | 21.75 | |

| SBF16.5-30-31-10.5 | 3/4 ID | 175 | 83 | 13.5 | 8 | 10.5 | 25.5 | 28.75 | 18.25 | 29.88 | 15.5 | 5.5 | 21.75 | |

| SBF16.5-30-31-10.5 | 1 ID | 125 | 83 | 13.5 | 8 | 10.5 | 25.5 | 28.75 | 18.25 | 29.88 | 15.5 | 5.5 | 21.75 | |

| SBF20-30-31-10.5 | 3/4 ID | 250 | 87 | 17 | 11.5 | 10.5 | 25.5 | 28.75 | 21.75 | 29.88 | 15.5 | 9 | 21.75 | |

| SBF20-30-31-10.5 | 1 ID | 150 | 87 | 17 | 11.5 | 10.5 | 25.5 | 28.75 | 21.75 | 29.88 | 15.5 | 9 | 21.75 | |

| SBF24-30-31-10.5 | 3/4 ID | 350 | 91 | 21 | 15.5 | 10.5 | 25.5 | 28.75 | 25.75 | 29.88 | 15.5 | 13 | 21.75 | |

| SBF24-30-31-10.5 | 1 ID | 250 | 91 | 21 | 15.5 | 10.5 | 25.5 | 28.75 | 25.75 | 29.88 | 15.5 | 13 | 21.75 | |

| SBF28-30-31-10.5 | 1 ID | 300 | 96 | 25.5 | 20 | 10.5 | 25.5 | 28.75 | 30.25 | 29.88 | 15.5 | 17.5 | 21.75 | |

| SBF34-30-31-10.5 | 1 ID | 350 | 103 | 31.5 | 26 | 10.5 | 25.5 | 28.75 | 36.25 | 29.88 | 15.5 | 23.5 | 21.75 | |

| SBF20-33-34-10.5 | 3/4 ID | 300 | 87 | 16.5 | 11.5 | 10.5 | 31.5 | 31.75 | 21.12 | 33.62 | 17.75 | 9 | 27.75 | |

| SBF20-33-34-10.5 | 1 ID | 200 | 87 | 16.5 | 11.5 | 10.5 | 31.5 | 31.75 | 21.12 | 33.62 | 17.75 | 9 | 27.75 | |

| SBAF32-19-21-10.5 | 3/4 ID | 175 | 106 | 29.5 | 24 | 10.5 | 20.5 | 21.62 | 34.38 | 21.5 | 12.12 | 21.5 | 16.75 | |

| SBAF32-19-21-10.5 | 1 ID | 85 | 106 | 29.5 | 24 | 10.5 | 20.5 | 21.62 | 34.38 | 21.5 | 12.12 | 21.5 | 16.75 | |

| SBAF24-23-24-10.5 | 3/4 ID | 150 | 99 | 21 | 15.5 | 10.5 | 20.5 | 23 | 25.88 | 23.5 | 12.12 | 13 | 16.75 | |

| SBAF24-23-24-10.5 | 1 ID | 125 | 99 | 21 | 15.5 | 10.5 | 20.5 | 23 | 25.88 | 23.5 | 12.12 | 13 | 16.75 | |

| SBAF30-23-24-10.5 | 3/4 ID | 225 | 108 | 27.5 | 22 | 10.5 | 20.5 | 23 | 32.38 | 23.5 | 12.12 | 19.5 | 16.75 | |

| SBAF30-23-24-10.5 | 1 ID | 200 | 108 | 27.5 | 22 | 10.5 | 20.5 | 23 | 32.38 | 23.5 | 12.12 | 19.5 | 16.75 | |

| SBAF38-23-24-10.5 | 3/4 ID | 300 | 120 | 35 | 29.5 | 10.5 | 20.5 | 23 | 41.75 | 23.5 | 12.12 | 27 | 16.75 | |

| SBAF38-23-24-10.5 | 1 ID | 250 | 120 | 35 | 29.5 | 10.5 | 20.5 | 23 | 41.75 | 23.5 | 12.12 | 27 | 16.75 | |

| SBAF28-25-26-10.5 | 3/4 ID | 275 | 113 | 25.5 | 20 | 10.5 | 25.5 | 24.75 | 32.25 | 27.88 | 15.5 | 17.5 | 21.75 | |

| SBAF28-25-26-10.5 | 1 ID | 175 | 113 | 25.5 | 20 | 10.5 | 25.5 | 24.75 | 32.25 | 27.88 | 15.5 | 17.5 | 21.75 | |

| SBAF34-25-26-10.5 | 3/4 ID | 350 | 119 | 31.5 | 26 | 10.5 | 25.5 | 24.75 | 38.25 | 27.88 | 15.5 | 23.5 | 21.75 | |

| SBAF34-25-26-10.5 | 1 ID | 250 | 119 | 31.5 | 26 | 10.5 | 25.5 | 24.75 | 38.25 | 27.88 | 15.5 | 23.5 | 21.75 | |

| SBAF16.5-30-31-10.5 | 3/4 ID | 175 | 103 | 13.5 | 8 | 10.5 | 25.5 | 28.75 | 18.38 | 29.88 | 15.5 | 5.5 | 21.75 | |

| SBAF16.5-30-31-10.5 | 1 ID | 125 | 103 | 13.5 | 8 | 10.5 | 25.5 | 28.75 | 18.38 | 29.88 | 15.5 | 5.5 | 21.75 | |

| SBAF20-30-31-10.5 | 3/4 ID | 250 | 107 | 17 | 11.5 | 10.5 | 25.5 | 28.75 | 21.88 | 29.88 | 15.5 | 9 | 21.75 | |

| SBAF20-30-31-10.5 | 1 ID | 150 | 107 | 17 | 11.5 | 10.5 | 25.5 | 28.75 | 21.88 | 29.88 | 15.5 | 9 | 21.75 | |

| SBAF24-30-31-10.5 | 3/4 ID | 350 | 111 | 21 | 15.5 | 10.5 | 25.5 | 28.75 | 27.75 | 29.88 | 15.5 | 13 | 21.75 | |

| SBAF24-30-31-10.5 | 1 ID | 250 | 111 | 21 | 15.5 | 10.5 | 25.5 | 28.75 | 27.75 | 29.88 | 15.5 | 13 | 21.75 | |

| SBAF28-30-31-10.5 | 1 ID | 300 | 116 | 25.5 | 20 | 10.5 | 25.5 | 28.75 | 32.25 | 29.88 | 15.5 | 17.5 | 21.75 | |

| SBAF34-30-31-10.5 | 1 ID | 350 | 123 | 31.5 | 26 | 10.5 | 25.5 | 28.75 | 38.25 | 29.88 | 15.5 | 23.5 | 21.75 | |

| SBAF20-33-34-10.5 | 3/4 ID | 300 | 107 | 16.5 | 11.5 | 10.5 | 31.5 | 31.75 | 23.25 | 33.62 | 17.75 | 9 | 27.75 | |

| SBAF20-33-34-10.5 | 1 ID | 200 | 107 | 16.5 | 11.5 | 10.5 | 31.5 | 31.75 | 23.25 | 33.62 | 17.75 | 9 | 27.75 | |

| SBEF32-19-21-10.5 | 3/4 ID | 175 | 106 | 29.5 | 24 | 10.5 | 20.5 | 21.62 | 34.38 | 21.5 | 12.12 | 21.5 | 16.75 | |

| SBEF32-19-21-10.5 | 1 ID | 85 | 106 | 29.5 | 24 | 10.5 | 20.5 | 21.62 | 34.38 | 21.5 | 12.12 | 21.5 | 16.75 | |

| SBEF24-23-24-10.5 | 3/4 ID | 150 | 99 | 21 | 15.5 | 10.5 | 20.5 | 23 | 25.88 | 23.5 | 12.12 | 13 | 16.75 | |

| SBEF24-23-24-10.5 | 1 ID | 125 | 99 | 21 | 15.5 | 10.5 | 20.5 | 23 | 25.88 | 23.5 | 12.12 | 13 | 16.75 | |

| SBEF30-23-24-10.5 | 3/4 ID | 225 | 128 | 27.5 | 22 | 10.5 | 20.5 | 23 | 32.38 | 23.5 | 12.12 | 19.5 | 16.75 | |

| SBEF30-23-24-10.5 | 1 ID | 200 | 128 | 27.5 | 22 | 10.5 | 20.5 | 23 | 32.38 | 23.5 | 12.12 | 19.5 | 16.75 | |

| SBEPF38-23-24-10.5 | 3/4 ID | 300 | 140 | 35 | 29.5 | 10.5 | 20.5 | 23 | 41.75 | 23.5 | 12.12 | 27 | 16.75 | |

| SBEPF38-23-24-10.5 | 1 ID | 250 | 140 | 35 | 29.5 | 10.5 | 20.5 | 23 | 41.75 | 23.5 | 12.12 | 27 | 16.75 | |

| SBEPF28-25-26-10.5 | 3/4 ID | 275 | 133 | 25.5 | 20 | 10.5 | 25.5 | 24.75 | 32.25 | 27.88 | 15.5 | 17.5 | 21.75 | |

| SBEPF28-25-26-10.5 | 1 ID | 175 | 133 | 25.5 | 20 | 10.5 | 25.5 | 24.75 | 32.25 | 27.88 | 15.5 | 17.5 | 21.75 | |

| SBEPF34-25-26-10.5 | 3/4 ID | 350 | 139 | 31.5 | 26 | 10.5 | 25.5 | 24.75 | 38.25 | 27.88 | 15.5 | 23.5 | 21.75 | |

| SBEPF34-25-26-10.5 | 1 ID | 250 | 139 | 31.5 | 26 | 10.5 | 25.5 | 24.75 | 38.25 | 27.88 | 15.5 | 23.5 | 21.75 | |

| SBEF16.5-30-31-10.5 | 3/4 ID | 175 | 103 | 13.5 | 8 | 10.5 | 25.5 | 28.75 | 18.38 | 29.88 | 15.5 | 5.5 | 21.75 | |

| SBEF16.5-30-31-10.5 | 1 ID | 125 | 103 | 13.5 | 8 | 10.5 | 25.5 | 28.75 | 18.38 | 29.88 | 15.5 | 5.5 | 21.75 | |

| SBEF20-30-31-10.5 | 3/4 ID | 250 | 107 | 17 | 11.5 | 10.5 | 25.5 | 28.75 | 21.88 | 29.88 | 15.5 | 9 | 21.75 | |

| SBEF20-30-31-10.5 | 1 ID | 150 | 107 | 17 | 11.5 | 10.5 | 25.5 | 28.75 | 21.88 | 29.88 | 15.5 | 9 | 21.75 | |

| SBEPF24-30-31-10.5 | 3/4 ID | 350 | 131 | 21 | 15.5 | 10.5 | 25.5 | 28.75 | 27.75 | 29.88 | 15.5 | 13 | 21.75 | |

| SBEPF24-30-31-10.5 | 1 ID | 250 | 131 | 21 | 15.5 | 10.5 | 25.5 | 28.75 | 27.75 | 29.88 | 15.5 | 13 | 21.75 | |

| SBEPF28-30-31-10.5 | 1 ID | 300 | 136 | 25.5 | 20 | 10.5 | 25.5 | 28.75 | 32.25 | 29.88 | 15.5 | 17.5 | 21.75 | |

| SBEPF34-30-31-10.5 | 1 ID | 350 | 143 | 31.5 | 26 | 10.5 | 25.5 | 28.75 | 38.25 | 29.88 | 15.5 | 23.5 | 21.75 | |

| SBEPF20-33-34-10.5 | 3/4 ID | 300 | 127 | 16.5 | 11.5 | 10.5 | 31.5 | 31.75 | 23.25 | 33.62 | 17.75 | 9 | 27.75 | |

| SBEPF20-33-34-10.5 | 1 ID | 200 | 127 | 16.5 | 11.5 | 10.5 | 31.5 | 31.75 | 23.25 | 33.62 | 17.75 | 9 | 27.75 | |

| No results available based on the combination of filters chosen above. Please choose a different combination of Reel Capacity/Rewind Option to show more results. | ||||||||||||||

- Specifications subject to change.

- A two-way flow hub is available and must be specified. Assembly is threaded on both ends so swivel joint can be attached at either end of the reel. A pipe cap seals the opposite end.

- Upon request, reels can be supplied with drum lengths other than shown and with disc sizes in other diameters.

- When ordering power rewind models, prefix number with:

SBA = Air Rewind (supplied with control valve and 18" air hose)

SBE = Electric Rewind (1/3 HP)

SBEP = Electric Rewind (1/2 HP) (12v and 24v DC rewind reels are supplied with switch and solenoid; 115v AC rewind reels are not supplied with switch, but can be ordered separately)

SBHD = Hydraulic Rewind (not supplied with control valve)

for example: SBEF32-19-21 - Reels handling 200' or more must use 1/2 HP motor. (Use prefix EP when ordering.)

- When installing FH-3 rollers add 4-1/2" to "D" dimension.

- Be sure to check dimensions and weights prior to ordering.

Note: A flexible connector must be used between the inlet pipe and the inlet swivel joint.

Request a Quote

To request a quote, simply complete the form below. It will then be quickly relayed to the person best able to assist you.