7500

Manual or Power Rewind Reels

To handle 1-1/4" or 1-1/2" I.D. hose

Fuel Dispensing / Bulk Transfer / Suction / Discharge

- Heavy-duty reel designed for longer lengths.

- Choose gear-driven crank rewind or chain and sprocket drive powered by an electric, hydraulic, or compressed air motor.

- Crank rewind reels supplied with pinion brake and power rewind reels with a comet brake.

- Standard inlet: 90° ball bearing swivel joint, 1-1/2" female NPT threads and 2" Victaulic® groove.

- Standard outlet: 1-1/2" female NPT threads.

- Standard: inlet, outlet riser, and hub assembly are steel. Options: also available in aluminum or stainless steel.

- Standard pressures to 1000 psi (41 bar), consult factory for other pressure ratings – must specify.

- Standard fluid temperatures from -20° F to +212 °F (-29° C to +100° C). Optional temperature ratings available - consult factory.

- Rollers and roller mounting brackets are accessory items. Specify roller position.

- Optional chain guard available.

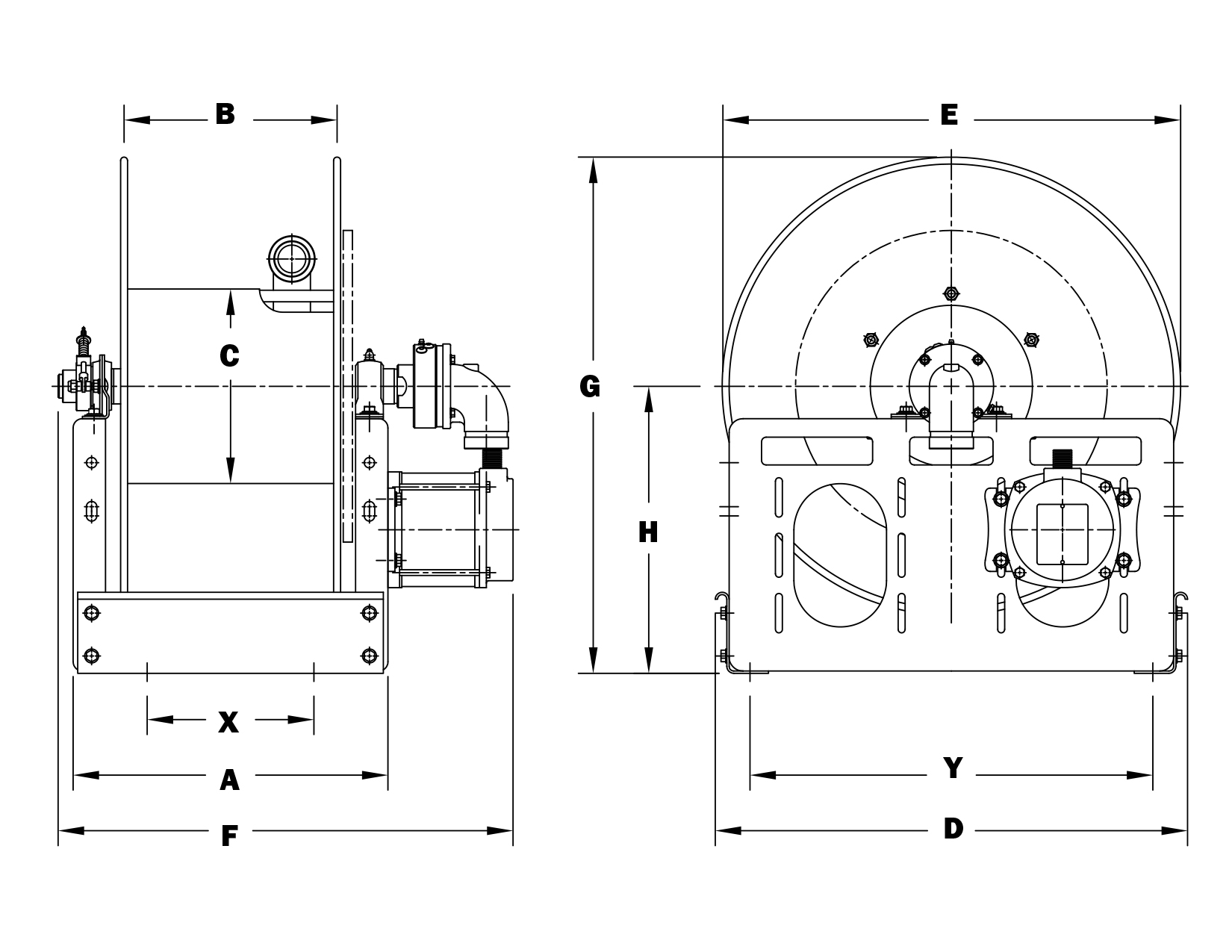

Models shown above represent standard configuration

Left: electric rewind (EP), Right: manual rewind

Reel Capacity, Dimensions and Details

Reel Capacity:

Rewind Option:

| MODEL | REEL CAPACITY (ft / lbs) | REEL DIMENSIONS (inches) | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Size | Length | Weight | A | B | C | D | E | F | G | H | X | Y | Relative Size | |

| 7528-19-21-10.5 | 1-1/4 ID | 70 | 104 | 25.5 | 20 | 10.5 | 20.5 | 18.75 | 32 | 21.5 | 12.12 | 17.5 | 16.75 | |

| 7528-19-21-10.5 | 1-1/2 ID | 50 | 104 | 25.5 | 20 | 10.5 | 20.5 | 18.75 | 32 | 21.5 | 12.12 | 17.5 | 16.75 | |

| 7538-23-24-10.5 | 1-1/4 ID | 175 | 130 | 35 | 29.5 | 10.5 | 20.5 | 22.75 | 41.5 | 23.5 | 12.12 | 27 | 16.75 | |

| 7538-23-24-10.5 | 1-1/2 ID | 100 | 130 | 35 | 29.5 | 10.5 | 20.5 | 22.75 | 41.5 | 23.5 | 12.12 | 27 | 16.75 | |

| 7520-25-26-10.5 | 1-1/4 ID | 75 | 106 | 17 | 11.5 | 10.5 | 25.5 | 24.75 | 23.5 | 27.88 | 15.5 | 9 | 21.75 | |

| 7520-25-26-10.5 | 1-1/2 ID | 50 | 106 | 17 | 11.5 | 10.5 | 25.5 | 24.75 | 23.5 | 27.88 | 15.5 | 9 | 21.75 | |

| 7528-25-26-10.5 | 1-1/4 ID | 125 | 123 | 25.5 | 20 | 10.5 | 25.5 | 24.75 | 32 | 27.88 | 15.5 | 17.5 | 21.75 | |

| 7528-25-26-10.5 | 1-1/2 ID | 100 | 123 | 25.5 | 20 | 10.5 | 25.5 | 24.75 | 32 | 27.88 | 15.5 | 17.5 | 21.75 | |

| 7522-30-31-10.5 | 1-1/4 ID | 125 | 118 | 19 | 13.5 | 10.5 | 25.5 | 28.75 | 25.5 | 29.88 | 15.5 | 11 | 21.75 | |

| 7522-30-31-10.5 | 1-1/2 ID | 100 | 118 | 19 | 13.5 | 10.5 | 25.5 | 28.75 | 25.5 | 29.88 | 15.5 | 11 | 21.75 | |

| 7528-30-31-10.5 | 1-1/4 ID | 200 | 131 | 25.5 | 20 | 10.5 | 25.5 | 28.75 | 32 | 29.88 | 15.5 | 17.5 | 21.75 | |

| 7528-30-31-10.5 | 1-1/2 ID | 150 | 131 | 25.5 | 20 | 10.5 | 25.5 | 28.75 | 32 | 29.88 | 15.5 | 17.5 | 21.75 | |

| 7526-33-34-10.5 | 1-1/4 ID | 200 | 133 | 22.5 | 17.5 | 10.5 | 31.5 | 31.75 | 29.25 | 33.62 | 17.75 | 15 | 27.75 | |

| 7526-33-34-10.5 | 1-1/2 ID | 175 | 133 | 22.5 | 17.5 | 10.5 | 31.5 | 31.75 | 29.25 | 33.62 | 17.75 | 15 | 27.75 | |

| A7528-19-21-10.5 | 1-1/4 ID | 70 | 124 | 25.5 | 20 | 10.5 | 20.5 | 18.75 | 33 | 21.5 | 12.12 | 17.5 | 16.75 | |

| A7528-19-21-10.5 | 1-1/2 ID | 50 | 124 | 25.5 | 20 | 10.5 | 20.5 | 18.75 | 33 | 21.5 | 12.12 | 17.5 | 16.75 | |

| A7538-23-24-10.5 | 1-1/4 ID | 175 | 150 | 35 | 29.5 | 10.5 | 20.5 | 22.75 | 42.5 | 23.5 | 12.12 | 27 | 16.75 | |

| A7538-23-24-10.5 | 1-1/2 ID | 100 | 150 | 35 | 29.5 | 10.5 | 20.5 | 22.75 | 42.5 | 23.5 | 12.12 | 27 | 16.75 | |

| A7520-25-26-10.5 | 1-1/4 ID | 75 | 126 | 17 | 11.5 | 10.5 | 25.5 | 24.75 | 24.5 | 27.88 | 15.5 | 9 | 21.75 | |

| A7520-25-26-10.5 | 1-1/2 ID | 50 | 126 | 17 | 11.5 | 10.5 | 25.5 | 24.75 | 24.5 | 27.88 | 15.5 | 9 | 21.75 | |

| A7528-25-26-10.5 | 1-1/4 ID | 125 | 143 | 25.5 | 20 | 10.5 | 25.5 | 24.75 | 33 | 27.88 | 15.5 | 17.5 | 21.75 | |

| A7528-25-26-10.5 | 1-1/2 ID | 100 | 143 | 25.5 | 20 | 10.5 | 25.5 | 24.75 | 33 | 27.88 | 15.5 | 17.5 | 21.75 | |

| A7522-30-31-10.5 | 1-1/4 ID | 125 | 138 | 19 | 13.5 | 10.5 | 25.5 | 28.75 | 26.5 | 29.88 | 15.5 | 11 | 21.75 | |

| A7522-30-31-10.5 | 1-1/2 ID | 100 | 138 | 19 | 13.5 | 10.5 | 25.5 | 28.75 | 26.5 | 29.88 | 15.5 | 11 | 21.75 | |

| A7528-30-31-10.5 | 1-1/4 ID | 200 | 151 | 25.5 | 20 | 10.5 | 25.5 | 28.75 | 33 | 29.88 | 15.5 | 17.5 | 21.75 | |

| A7528-30-31-10.5 | 1-1/2 ID | 150 | 151 | 25.5 | 20 | 10.5 | 25.5 | 28.75 | 33 | 29.88 | 15.5 | 17.5 | 21.75 | |

| A7526-33-34-10.5 | 1-1/4 ID | 200 | 153 | 22.5 | 17.5 | 10.5 | 31.5 | 31.75 | 30.25 | 33.62 | 17.75 | 15 | 27.75 | |

| A7526-33-34-10.5 | 1-1/2 ID | 175 | 153 | 22.5 | 17.5 | 10.5 | 31.5 | 31.75 | 30.25 | 33.62 | 17.75 | 15 | 27.75 | |

| EP7528-19-21-10.5 | 1-1/4 ID | 70 | 144 | 25.5 | 20 | 10.5 | 20.5 | 18.75 | 33 | 21.5 | 12.12 | 17.5 | 16.75 | |

| EP7528-19-21-10.5 | 1-1/2 ID | 50 | 144 | 25.5 | 20 | 10.5 | 20.5 | 18.75 | 33 | 21.5 | 12.12 | 17.5 | 16.75 | |

| EP7538-23-24-10.5 | 1-1/4 ID | 175 | 170 | 35 | 29.5 | 10.5 | 20.5 | 22.75 | 42.5 | 23.5 | 12.12 | 27 | 16.75 | |

| EP7538-23-24-10.5 | 1-1/2 ID | 100 | 170 | 35 | 29.5 | 10.5 | 20.5 | 22.75 | 42.5 | 23.5 | 12.12 | 27 | 16.75 | |

| EP7520-25-26-10.5 | 1-1/4 ID | 75 | 146 | 17 | 11.5 | 10.5 | 25.5 | 24.75 | 24.5 | 27.88 | 15.5 | 9 | 21.75 | |

| EP7520-25-26-10.5 | 1-1/2 ID | 50 | 146 | 17 | 11.5 | 10.5 | 25.5 | 24.75 | 24.5 | 27.88 | 15.5 | 9 | 21.75 | |

| EP7528-25-26-10.5 | 1-1/4 ID | 125 | 163 | 25.5 | 20 | 10.5 | 25.5 | 24.75 | 33 | 27.88 | 15.5 | 17.5 | 21.75 | |

| EP7528-25-26-10.5 | 1-1/2 ID | 100 | 163 | 25.5 | 20 | 10.5 | 25.5 | 24.75 | 33 | 27.88 | 15.5 | 17.5 | 21.75 | |

| EP7522-30-31-10.5 | 1-1/4 ID | 125 | 158 | 19 | 13.5 | 10.5 | 25.5 | 28.75 | 26.5 | 29.88 | 15.5 | 11 | 21.75 | |

| EP7522-30-31-10.5 | 1-1/2 ID | 100 | 158 | 19 | 13.5 | 10.5 | 25.5 | 28.75 | 26.5 | 29.88 | 15.5 | 11 | 21.75 | |

| EP7528-30-31-10.5 | 1-1/4 ID | 200 | 171 | 25.5 | 20 | 10.5 | 25.5 | 28.75 | 33 | 29.88 | 15.5 | 17.5 | 21.75 | |

| EP7528-30-31-10.5 | 1-1/2 ID | 150 | 171 | 25.5 | 20 | 10.5 | 25.5 | 28.75 | 33 | 29.88 | 15.5 | 17.5 | 21.75 | |

| EP7526-33-34-10.5 | 1-1/4 ID | 200 | 173 | 22.5 | 17.5 | 10.5 | 31.5 | 31.75 | 30.25 | 33.62 | 17.75 | 15 | 27.75 | |

| EP7526-33-34-10.5 | 1-1/2 ID | 175 | 173 | 22.5 | 17.5 | 10.5 | 31.5 | 31.75 | 30.25 | 33.62 | 17.75 | 15 | 27.75 | |

| HD7528-19-21-10.5 | 1-1/4 ID | 70 | 124 | 25.5 | 20 | 10.5 | 20.5 | 18.75 | 33 | 21.5 | 12.12 | 17.5 | 16.75 | |

| HD7528-19-21-10.5 | 1-1/2 ID | 50 | 124 | 25.5 | 20 | 10.5 | 20.5 | 18.75 | 33 | 21.5 | 12.12 | 17.5 | 16.75 | |

| HD7538-23-24-10.5 | 1-1/4 ID | 175 | 150 | 35 | 29.5 | 10.5 | 20.5 | 22.75 | 42.5 | 23.5 | 12.12 | 27 | 16.75 | |

| HD7538-23-24-10.5 | 1-1/2 ID | 100 | 150 | 35 | 29.5 | 10.5 | 20.5 | 22.75 | 42.5 | 23.5 | 12.12 | 27 | 16.75 | |

| HD7520-25-26-10.5 | 1-1/4 ID | 75 | 126 | 17 | 11.5 | 10.5 | 25.5 | 24.75 | 24.5 | 27.88 | 15.5 | 9 | 21.75 | |

| HD7520-25-26-10.5 | 1-1/2 ID | 50 | 126 | 17 | 11.5 | 10.5 | 25.5 | 24.75 | 24.5 | 27.88 | 15.5 | 9 | 21.75 | |

| HD7528-25-26-10.5 | 1-1/4 ID | 125 | 143 | 25.5 | 20 | 10.5 | 25.5 | 24.75 | 33 | 27.88 | 15.5 | 17.5 | 21.75 | |

| HD7528-25-26-10.5 | 1-1/2 ID | 100 | 143 | 25.5 | 20 | 10.5 | 25.5 | 24.75 | 33 | 27.88 | 15.5 | 17.5 | 21.75 | |

| HD7522-30-31-10.5 | 1-1/4 ID | 125 | 138 | 19 | 13.5 | 10.5 | 25.5 | 28.75 | 26.5 | 29.88 | 15.5 | 11 | 21.75 | |

| HD7522-30-31-10.5 | 1-1/2 ID | 100 | 138 | 19 | 13.5 | 10.5 | 25.5 | 28.75 | 26.5 | 29.88 | 15.5 | 11 | 21.75 | |

| HD7528-30-31-10.5 | 1-1/4 ID | 200 | 151 | 25.5 | 20 | 10.5 | 25.5 | 28.75 | 33 | 29.88 | 15.5 | 17.5 | 21.75 | |

| HD7528-30-31-10.5 | 1-1/2 ID | 150 | 151 | 25.5 | 20 | 10.5 | 25.5 | 28.75 | 33 | 29.88 | 15.5 | 17.5 | 21.75 | |

| HD7526-33-34-10.5 | 1-1/4 ID | 200 | 153 | 22.5 | 17.5 | 10.5 | 31.5 | 31.75 | 30.25 | 33.62 | 17.75 | 15 | 27.75 | |

| HD7526-33-34-10.5 | 1-1/2 ID | 175 | 153 | 22.5 | 17.5 | 10.5 | 31.5 | 31.75 | 30.25 | 33.62 | 17.75 | 15 | 27.75 | |

| No results available based on the combination of filters chosen above. Please choose a different combination of Reel Capacity/Rewind Option to show more results. | ||||||||||||||

- Specifications subject to change.

- Upon request, reels can be supplied with drum lengths other than shown and with disc sizes in other diameters.

- Dimensions shown for reels up to and including 30-31 disc size reflect pressed frames. All others are roll-formed channel frames.

- When ordering power rewind models, prefix model number with:

A = Air Rewind (supplied with control valve and 18" air hose)

EP = Electric Rewind (1/2 HP) (12v and 24v DC are supplied with non-explosion proof switch and solenoid, 115v AC are not supplied with switch, order separately)

HD = Hydraulic Rewind (not supplied with control valve)

MX = Chain Drive Crank - Be sure to check dimensions and weights prior to ordering.

Note: A flexible connector must be used between the inlet pipe and the inlet swivel joint.

Some of the larger models may require a clutch reduction unit depending on your application.

Request a Quote

To request a quote, simply complete the form below. It will then be quickly relayed to the person best able to assist you.