CALL SALES: 518-797-3791

CALL SALES: 518-797-3791

Reel Tune-ups with Convenient Maintenance Solutions

Posted on 01/16/2023

A reel that works as hard as you do may need a little tune-up every now and then. Hannay’s reels have been the industry standard for over 85 years—not only for their superior craftsmanship and durability, but for their ease-of-maintenance, built-in safety features, and convenient repairs, even at the toughest jobsites. Keep reading to learn more about our maintenance-friendly reels and our video resource library, full of servicing tips, installation how-tos and general safety guidelines—for when your equipment needs a little TLC.

Even with a durable build like ours, wear and tear are a natural part of the lifecycle of your reel. The strongest parts and materials still require routine maintenance during frequent usage to ensure optimal performance. Hannay understands that when your equipment is down, so is your productivity.

Preventive maintenance is critical to ensuring you get maximum productivity from your reel. In our continuing effort to servicing the needs of our customers—long after initial purchase—Hannay has developed “Maintenance and Installation Guides” with detailed instructions of everything reels. Information is available on installing hose and roller assemblies, lubricating and changing packing seals on swivel joints, collector ring maintenance on cable reels, bearing replacement, motor installation and troubleshooting, and more. You will find parts-specific maintenance guidelines and quick-install instructions to help you make repairs quickly and efficiently, while keeping your work and workers safe.

Hannay knows that safety is at the forefront of any operation, big or small. From jobsite applications to equipment handling, Hannay designs its reels with the safety and productivity of your entire operation in mind. A detailed Safety Guideline brochure comes with every reel.

Hannay recommends following these general safety guidelines to ensure the welfare of your workers and jobsite:

- Perform inspections and suggested routine maintenance on reel frames, discs, fluid paths, motors and swivel joints—give the reel a once-over every month to make sure everything is in working order

- Ensure components are clean, tightened, and mechanically sound

- Check all electrical connections on motors and on cable reel collector assemblies

- Avoid exceeding the maximum pressure designed for the hose reel’s psi rating

- Use ball stops on spring rewind reels, never let go of hose or cable when rewinding on a spring reel, and never remove cover containing the spring motor

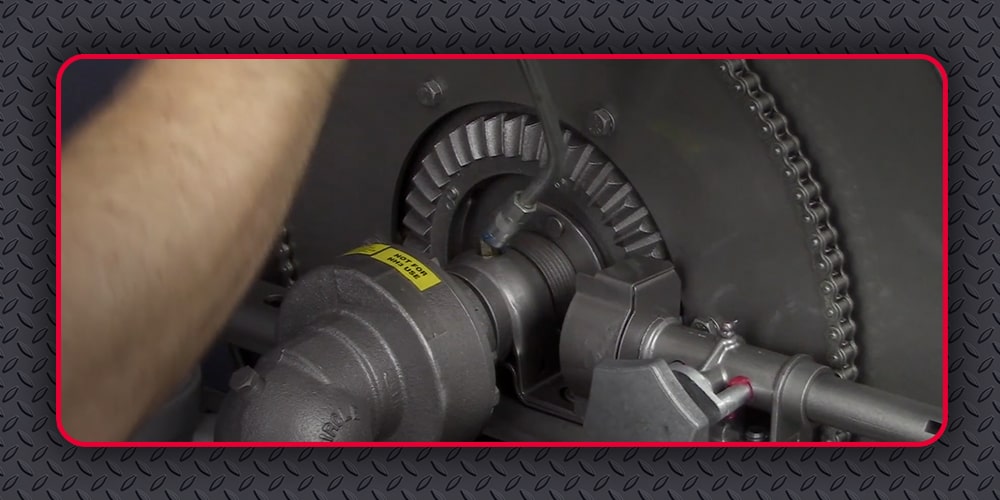

- Beware of pinch point areas, and always use caution when operating near chain and sprockets

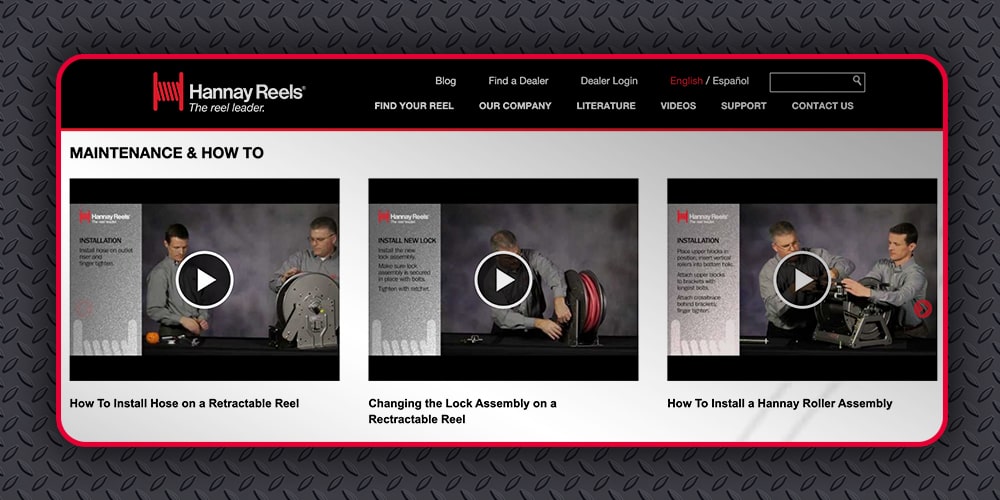

Don’t let repairs and maintenance interrupt your job. Hannay’s video library at hannay.com is your one-stop resource for replacement, installation, and troubleshooting tips to help you throughout the lifecycle of your reel. With step-by-step maintenance tutorials from Hannay experts to customer testimonials, featured reel highlights, and ordering support, our videos have you covered with everything reels. Check out all these resources and more at hannay.com today and learn why Hannay Reels remains “the reel leader.”

Share This

Industries: General Education

Applications: General Education

Back

Industries

Applications

- All

- Air / Pneumatic Tools

- Audio / Video / Fiber Optic

- Booster Hose (Fire Protection)

- Breathing Air

- Cable Storage Only (Not Live)

- Chemical / Corrosive

- Electric Cord

- Fire/Rescue - Electric Cord

- Fire/Rescue - Hydraulic Tools

- Fire/Rescue - Utility or Breathing Air

- Flat Hose (Fire Protection)

- Food/Beverage Grade

- Fuel - DEF

- Fuel - LP Gas

- Fuel - Petroleum/Gas/Diesel

- Grounding (Static)

- Grounding (Utility)

- Hydraulic Tools

- Jetting/Water Blasting

- Lawn Care/Spray/Pest Control

- Lubrication / Grease

- Pest Control

- Pipeline Inspection (Video)

- Pressure Wash / Washdown

- Refueling (Diesel/Gas)

- Spray

- Vacuum/Suction

- Water Supply

- Welding - Arc

- Welding - Gas

- General Education