PBGMB

Power Rewind Reels

To handle single 1" or 1-1/2" I.D. hose

LP Gas / Propane / Refueling

- Standard hose reel is steel construction, painted graphite. Aluminum or stainless steel construction is available.

- "SB" prefix denotes polished aluminum construction, offering both reduced weight and superior corrosion resistance compared to standard steel construction.

- Choose #40 chain and sprocket drive powered by an electric, hydraulic, compressed air or direct drive hydraulic rewind motor.

- Auxiliary crank rewind standard on HDDPB Series reels. Available on PB Series power rewind reels, at extra cost.

- Direct drive hydraulic rewind reels supplied with pinion brake. Electric powered rewind reels supplied with strap brake.

- Other brake and locking devices may be specified. See Ordering & Accessory Guide.

- Standard inlet: 90° ball bearing swivel joint with 1-1/2" female NPT threads.

- Standard outlet: 1" female NPT threads. Other sizes and/or threads can be furnished and must be specified.

- Standard inlet, outlet riser, and hub assembly are steel.

- Pressures to 350 psi (24 bar). Standard fluid temperatures from -40° F to +300° F (-40° C to +149° C). Optional pressure and temperature ratings available - consult factory.

- Consult factory for other pressures and temperatures.

- Chain guard available upon request, must be specified.

- Assembly B bottom wind roller is standard.

Model shown above represents standard configuration

Jump to:

Reel Capacity, Dimensions and Details

ISO Parts Drawing

Service Information

Reel Capacity, Dimensions and Details

Reel Capacity:

Show:

Rewind Option:

Show:

Measurements: Standard / Metric

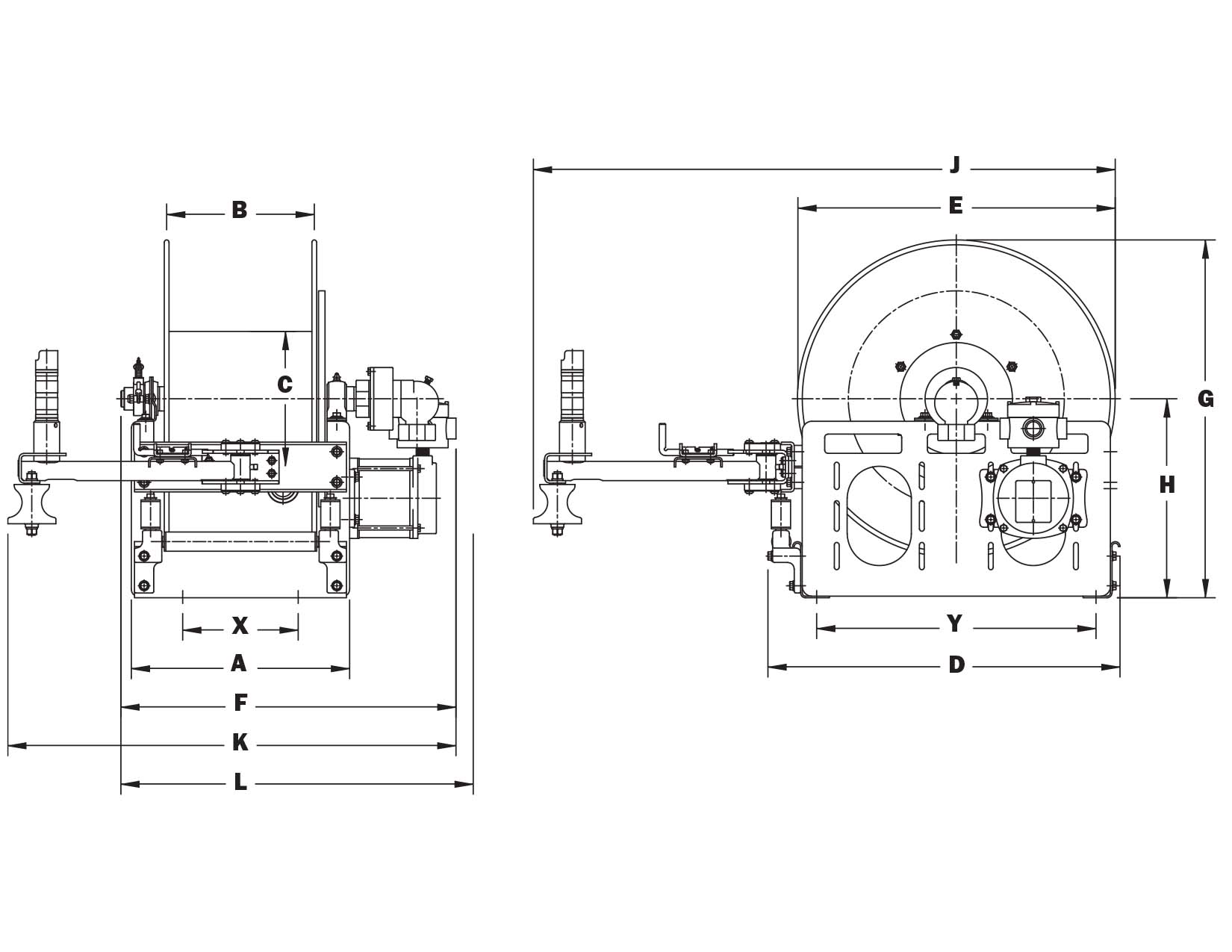

| MODEL | REEL CAPACITY (ft / lbs) | REEL DIMENSIONS (inches) | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Size | Length | Weight | A | B | C | D | E | F | G | H | X | Y | Relative Size | |

| APBGMB24-23-24 | 1 ID | 125 | 160 | 21 | 15.5 | 10.5 | 20.5 | 22.75 | 29.25 | 23.5 | 12.12 | 13 | 16.75 | |

| APBGMB30-23-24 | 1 ID | 150 | 170 | 27.5 | 22 | 10.5 | 20.5 | 22.75 | 35.75 | 23.5 | 12.12 | 19.5 | 16.75 | |

| APBGMB26-25-26 | 1 ID | 150 | 185 | 23 | 17.5 | 10.5 | 25.5 | 24.75 | 31.25 | 27.88 | 15.5 | 15 | 21.75 | |

| APBGMB28-25-26 | 1 ID | 200 | 191 | 25.5 | 20 | 10.5 | 25.5 | 24.75 | 33.75 | 27.88 | 15.5 | 17.5 | 21.75 | |

| APBGMB22-30-31 | 1 ID | 250 | 188 | 19 | 13.5 | 10.5 | 25.5 | 28.75 | 27.25 | 29.88 | 15.5 | 11 | 21.75 | |

| APBGMB18-33-34 | 1 ID | 200 | 175 | 14.5 | 9.5 | 10.5 | 31.5 | 31.75 | 23.75 | 33.62 | 17.75 | 7 | 27.75 | |

| EPBGMB24-23-24 | 1 ID | 125 | 160 | 21 | 15.5 | 10.5 | 20.5 | 22.75 | 29.25 | 23.5 | 12.12 | 13 | 16.75 | |

| EPBGMB30-23-24 | 1 ID | 150 | 170 | 27.5 | 22 | 10.5 | 20.5 | 22.75 | 35.75 | 23.5 | 12.12 | 19.5 | 16.75 | |

| EPBGMB26-25-26 | 1 ID | 150 | 185 | 23 | 17.5 | 10.5 | 25.5 | 24.75 | 31.25 | 27.88 | 15.5 | 15 | 21.75 | |

| EPBGMB28-25-26 | 1 ID | 200 | 191 | 25.5 | 20 | 10.5 | 25.5 | 24.75 | 33.75 | 27.88 | 15.5 | 17.5 | 21.75 | |

| EPBGMB22-30-31 | 1 ID | 250 | 188 | 19 | 13.5 | 10.5 | 25.5 | 28.75 | 27.25 | 29.88 | 15.5 | 11 | 21.75 | |

| EPBGMB18-33-34 | 1 ID | 200 | 175 | 14.5 | 9.5 | 10.5 | 31.5 | 31.75 | 23.75 | 33.62 | 17.75 | 7 | 27.75 | |

| No results available based on the combination of filters chosen above. Please choose a different combination of Reel Capacity/Rewind Option to show more results. | ||||||||||||||

- Specifications subject to change.

- Upon request, reels can be supplied with drum lengths other than shown and with disc sizes in other diameters.

- Consult factory for reels using 1-1/2" ID hose.

- When ordering power rewind models, prefix model number with:

A = Air Rewind (supplied with control valve and 25" air hose)

E = Explosion Proof Electric Rewind (2/3 HP) (supplied with explosion proof switch, solenoid, and junction box)

HD = Hydraulic Rewind (not supplied with control valve)

HDD = Direct Drive Hydraulic Rewind (not supplied with control valve) - When ordering A, HD and HDD rewind reels deduct 20 lbs. from ship weight.

- Dimensions J, K, L not shown in chart, consult factory for dimension specifics.

Dimension J is maximum, with Guidemaster® in operating position.

Dimension K is maximum, with Guidemaster® in traveling position opposite rewind motor, as shown in dimensional drawing

Dimension L is maximum, with Guidemaster® in traveling position on same side as rewind motor. - Guidemaster® weight is approximately 21 lbs. Guidemasters® are shipped as parts.

- Be sure to check dimensions and weights prior to ordering.

Note: A flexible connector must be used between the inlet pipe and the inlet swivel joint.

ISO Parts Drawing

ISO-202 Alumimum Construction SBPBGMB Series (manual or power rewind (≤30" disc size)ISO-204 Alumimum Construction SBPBGMB Series (manual or power rewind (≤36" disc size)

ISO-201 Stainless Steel Construction PBGMB Series (manual or power rewind ≤30" disc size)

ISO-203 Stainless Steel Construction PBGMB Series (manual or power rewind ≤36" disc size)

ISO-264 Steel Construction PBGMB Series (manual or power rewind ≤30" disc size)

ISO-271 Steel Construction PBGMB Series (manual or power rewind ≤36" disc size)

ISO-267 Hannay Guidemaster® (GM-X)

ISO-200 Guidemaster® Brackets

ISO-263 Guidemaster® Assembly B Rollers

Request a Quote

To request a quote, simply complete the form below. It will then be quickly relayed to the person best able to assist you.